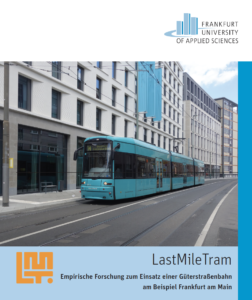

Frankfurt University’s Research Lab for Urban Transport (ReLUT) and Frankfurt am Main of Applied Sciences (Frankfurt UAS) did research on the use of rail networks (trams) for city logistics. During a pilot, delivery processes were tested together with VGF and Hermes. The test has shown that it is technically possible to use a tram for parcel deliveries.

An analysis of the tram network in Frankfurt showed that the existing public transport infrastructure for the handling of goods is suitable for deliveries to many locations. As part of the project, criteria for loading and unloading were defined. It is crucial that passenger operations are not disrupted. Also, space available at the platforms is important. For the use of roll containers, the platforms must enable loading or unloading at ground level.

Currently, there a no standardized transport boxes (containers) on the market that are suitable for use in trams. Boxes must be compatible with the tram and with common cargo bike systems. In addition, the transport boxes should be easy to close, weatherproof, rollable, and be safe from vandalism. On this basis, transport boxes were developed and prototypes were made.

The modeling shows that 89 delivery vehicles can be replaced by 223 transport boxes per day when a transport box contains 60 parcels. A cargo cyclist can deliver the transport boxes each shift. A parcel delivered with the tram costs € 1.89 and a parcel with a conventional van costs € 1.62. However, the tram concept is better in terms of CO2 savings; reduction 57% of CO2 emissions can be realized (based on diesel vans).

Further research

For a large-scale implementation of the cargo tram delivery concept, further research is necessary. On the one hand, there are legal and liability issues. It is currently not legal to transport people and goods together in a tram. It must also be clear who is liable for damage at what time. Another important factor is infrastructure. Storage areas for cargo bikes and for intermediate storage of the transport boxes and parcels must be found.

All processes must be seamlessly integrated into planning. In a logistics process that involves a large number of transport boxes to be transported and where there are many participants in the process, it is important to develop a system that controls the material flow (of transport boxes) and the value flow (money) and is able to localize each transport box (Track & Trace). Data must be exchanged along the end-to-end logistics chain. Synchronizing delivery staff and transport boxes is essential. In the future it might also possible to move goods to underground systems.

Source: Frankfurt University

More information; click here.