The e-commerce sector is working on sustainable deliveries of online orders. The delivery vans now quickly become electric. They try to deliver first-time-right. Focus on fewer returns. And, the warehouses are super sustainable. But how many large boxes are not delivered carrying only one silly little product?

Packaging

Together with web stores and suppliers, Dutch Thuiswinkel.org has set the goal of reducing air in parcels with 10% in 2022. In addition, the e-commerce sector is focusing on eliminating shipping packages altogether, where possible.

These goals are set in the Packaging Delivery Plan 2019-2022. To be able to deliver products without damage to the consumer, the packaging is often necessary. In addition, it is also important that the parcel is not too large.

The air in parcels results in unnecessary CO2 emissions during distribution. With less air in parcels, the parcels become smaller, more parcels can be transported in one trip and fewer delivery vehicles are needed.

The objectives of the packaging plan include:

- A shipping package will only be applied if one or more packaging reasons apply, where marketing may not be the only reason for packaging.

- Stop using filling materials, only when this is strictly necessary for the protection of the product.

- Reduction of 10% air compared to 2018.

- 10% more reusable packaging.

- All shipping bags are resealable. Consumers get information on how to separate the packaging.

- Use of recycled plastic.

- Cardboard packaging is made from FSC / PEFC material and contains as many recycled fibers as possible.

In recent years, web stores have already been working with on demand packaging and reducing packaging material. One hundred percent less air is not feasible. Products come in all possible forms, so it is inevitable that there is air in packaging.

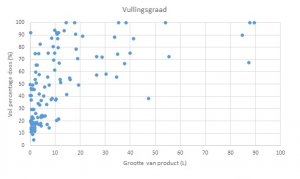

Degree of filling

A study by the Dutch Thuiswinkel.org and Top Sector Logistics shows that when more products are packed together, the better the box is filled. At the end of 2018, Partners for Innovation carried out a study of the air in parcels. Web shops use different packaging methods. The most common is the cardboard box (75%), followed by the plastic bag (19%). The degree of filling of envelopes and shipping bags is much higher than for boxes; almost 100%. However, because a bag offers less protection, not all types of products can be shipped this way. With a cardboard box, the filling level is ‘average’ 50%. Large web stores on average perform slightly better than small web stores.

The clothing and electronics sectors have a high filling rate. The clothing sector performs better than average with a filling rate of boxes of on average 60%. Clothing is a soft product and therefore easy to mold to the box in which it is packaged. Electronics products are often already in a sturdy box and are dimensionally stable, so there is no need for an additional shipping packaging. Larger electronics products are often shipped without a shipping box. Larger products are packed more efficiently than small products.

The graph shows that for smaller products (less than 10 liters, and that by far is the biggest category of shipments), the filling level is below 30 percent! Small products often need a minimum package size because otherwise they are easily lost. The smallest standard box is still considerably larger than small products, which results in a lower degree of filling for these products.

Ambitious?

The objective of reducing air in parcels by 10% by 2022 is somewhat meager given the results of the study. On the other hand, the development of ‘e-commerce ready’ packaging is a challenge for the entire supply chain, not just for the web stores. Smart online logistics processes start with the producers. In addition, the automated warehouse and sorting processes must be adapted to cope with the greater diversity of package sizes and forms. Perhaps this is also a good opportunity to think about using RFID.

Walther Ploos van Amstel.